product impact test|how does an impact test work : white label An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a . Resultado da Go to hiddenlol.com, switch to desktop version if on mobile, top right shows 'instantfap' in red letters, click on it. There's still lots with errors but it's something. Enjoy! ludwigjager. • 4 yr. ago.

{plog:ftitle_list}

WEBAssistir séries online grátis ficou muito mais fácil no nosso site, basta escolher sua série online e ver de graça com a melhor qualidade.

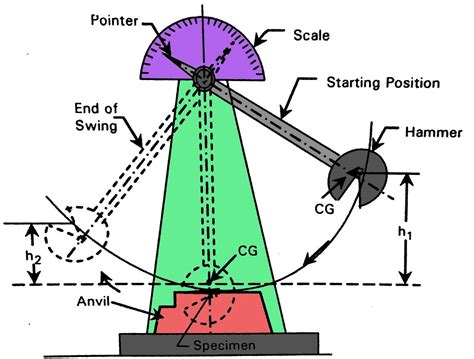

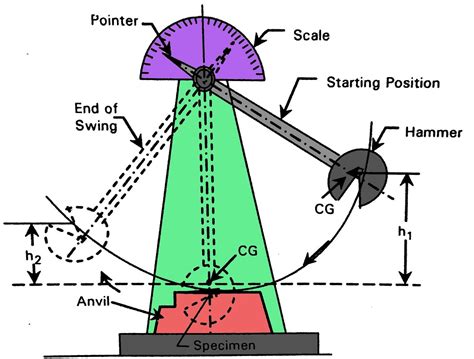

Impact tests are short-term tests which provide information on the failure behavior of materials or components subjected to rapid loading and at varying temperatures. The testing systems used for these tests are either pendulum impact testers or drop-weight testers.ZwickRoell has been delivering quality impact test equipment for years. Our .

why impact testing is done

An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion.Product drop testing and package drop testing provide insight into their design by evaluating how well items withstand tumbles, drops, and other types of impact throughout their lifecycle. Armed with this information, manufacturers can .

Impact testing equipment plays a vital role in the design and development of products. Manufacturers use impact testing to choose the most reliable materials for their products. It can help ensure that they meet the necessary performance and safety standards. Testing can also optimize and improve existing designs. The end product is better .

Analyze user behavior, conversion rates, and performance indicators to gauge the impact of testing on your product’s success. This data-driven approach to project monitoring helps in making informed decisions. Remember, the product testing process is a continuous journey. Plan for regular testing and updates post-launch to ensure your product . Drop weight impact test calculations measure the toughness of polymers and composites used in many automotive and aerospace applications. Ensuring that these calculations are as accurate as possible is critical. . This way, OEMs can prevent downtime and product recalls further down the supply chain. Choosing your Drop Weight Impact Testing .Impact tests require the use of specialised impact testing machines. These machines are designed to generate controlled impacts on samples and precisely measure the change in properties of the material or product under test. Impact testing machines are essential to ensure that tests are accurate, reproducible and comply with standards. Impact testing is widely used in various industries to ensure the safety and durability of products. Understanding the principles of impact testing is essential for designing and manufacturing products that can withstand sudden impacts and shocks.

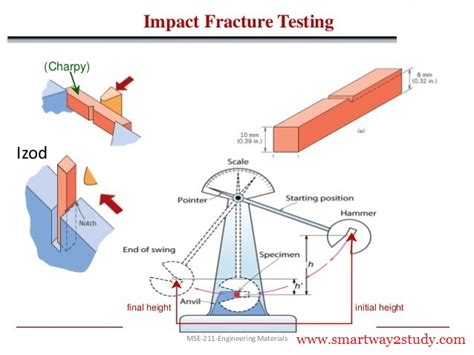

ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion. See our milestones here and access our press releases here.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

Impact testing plays a crucial role in material science, engineering and product development by providing insights into a material’s response to sudden loads. By measuring a material’s resistance to impact and facture behaviour, our tests can support you in designing safer, more reliable products.Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.Izod Impact Test Understanding the Izod Impact Test: A Comprehensive Guide Introduction In the realm of materials testing, the Izod Impact Test stands out as a critical method for assessing the impact strength of plastics and other polymers. This test, integral to the offerings at Kiyo R&D Center & Laboratory, is a dynamic means to [.]

Impact Testing It is the measure of a material’s resistance to the sudden application of force. Measuring properties like plastic deformation, ductility, and brittleness of materials is essential for proper material selection, ensuring quality control and reliability for finished products. Depending on the sample requirements, experts choose .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion. See our .ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion. See our milestones here and access our press releases here.

ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion. See our milestones here and access our press releases here.ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion. See our milestones here and access our press releases here. Let's look at the impact test machine (or Charpy impact tester) commonly used for assessing the impact resistance of products and materials.You'll learn:☑ Wh. The Izod / Charpy Impact Test represents a pivotal evaluation method in the material science industry, serving as a fundamental measure of a material's toughness and resistance to impact at varying temperatures. This testing methodology is critical for assessing the durability of plastics, metals, and ceramics under sudden stresses. Administered using .

For windows and doors, the impact test consists of firing a 2x4 projectile at predetermined locations. The cycling portion of the test is conducted after the impact test with no penetrations and consists of 9,000 cycles of positive and negative pressures. . Air, Water, and Structural testing; Florida Product Approval requirements; Miami-Dade .

Impact testing has become firmly established in materials and components testing. The properties determined are part of basic material characterization. ZwickRoell has been delivering quality impact test equipment for years. Our product line includes pendulum impact testers for metals and pendulum impact testers for plastics, .Drop Weight Impact Testers. Instron Drop Towers are used to develop, fine tune, and validate material models. The new 9400 Series produces reliable, repeatable results whether you are testing materials and components before production to improve product acceptance or testing during production to ensure continuous improvement.

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .A noninstrumented impact test only measures the energy required to break the specimen, whereas an instrumented impact test also measures the force history during the impact, see figure 2.21. In the instrumented impact tests, the pendulum’s hammer is equipped with a load cell, and the impact data are stored using a high-speed data acquisition .

what is an impact test

Impact testing is a critical step in ensuring the safety of plastic products. This article explains the importance of impact testing and how to perform it. . In the end, the choice of impact testing type depends on the goal. Product design, material characterisation, quality control, inspecting incoming material, and R&D are a few of the .

iphone drop test pop its

types of impact testing

Resultado da La red mexicana global. Vívaro es la consolidación de más de cinco décadas de innovación tecnológica y servicios de telecomunicaciones.

product impact test|how does an impact test work